WE PUT INSIGHTS INTO ACTION.

We don’t follow the trends – we set them. TFS leverages 25 years of industry data and unmatched expertise to deliver brand-independent solutions that put our clients first. The result? Measurable outcomes and lasting impact.

Spend less.

See everything.

Prove the ROI.

We give procurement leaders full visibility into their fleet spend – and we welcome being held accountable to the results.

TFS delivers:

100% visibility to total cost of ownership

Guaranteed savings targets (starting at 15%)

Supplier accountability and performance tracking

Optimized utilization, safety and reliability

You don’t have to chase results. We deliver them.

Keep your fleet running. Keep your floor moving.

Downtime kills productivity. We eliminate it.

TFS gives you:

Timely replacement of aging equipment

Serial number-level tracking and proactive maintenance

Supplier accountability on uptime and cost

Cost-per-hour KPIs to track performance and spot inefficiencies

We stay integrated and prevent problems so you can focus on production.

We Don't Just Advise. We Execute.

TFS isn’t here to give you a plan and walk away. We roll up our sleeves, stay integrated alongside you and deliver the results we promise — with full visibility and accountability every step of the way.

We Get on the Floor

We walk your facility, meet your teams, and assess your fleet where it’s used — not from a spreadsheet.

We Turn Insight into Action

We combine real-time data with decades of operational expertise to find savings, reduce downtime and right-size your fleet.

We Do the Work With You

You don’t just get a roadmap — you get an execution partner. We manage suppliers, equipment, timelines, lessors, and results.

We Track, Prove and Improve

Every decision is measured. Every improvement is reported. Every dollar saved is documented. and visualized in a live dashboard. So you’ll be able to focus on what matters.

See our process in action.

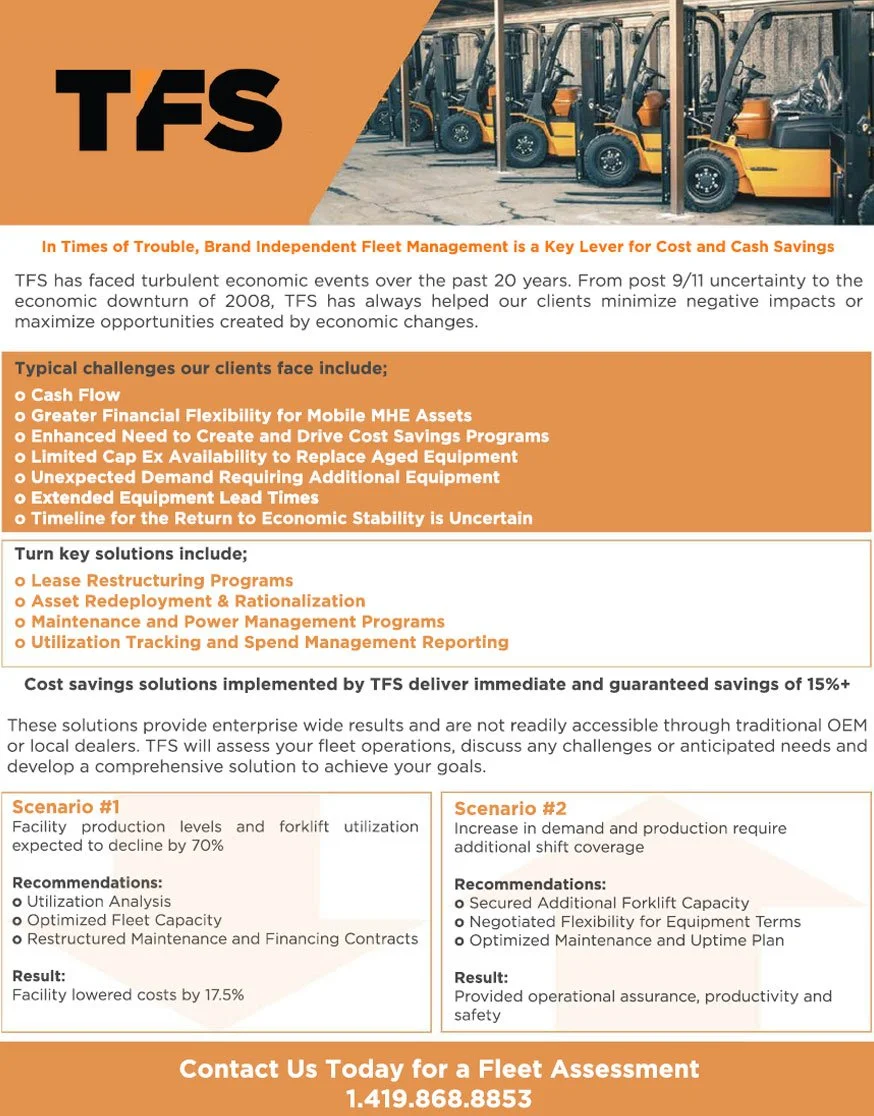

Two Clients, One Proven Result

Explore how TFS delivered fleet standardization, uptime guarantees and measurable cost savings across multiple sites.

From Injury to Innovation

How a tire manufacturer achieved 100% uptime and slashed total cost of ownership.